Control Engineering Services for

Pharmaceutical Industry

CONSULTANCY TRAINING EXAMPLES OF OUR WORK

Consultancy

ISC provides independent, high quality control engineering consultancy services to the pharmaceutical industries.

ISC specialises in:

- Solving difficult practical control problems that other suppliers have looked at but failed to solve.

- Optimal control design and parameters that yield the most profitable or best way of operating a plant or system.

- High-fidelity dynamic simulation for:

- Benefits analysis of process and control modifications.

- De-risking the design and commissioning of new process equipment and control systems.

- Re-tuning troublesome control loops.

- Software engineering services - such as requirements capture, development, and process connectivity and data exchange via industry-standard communication protocols such as OPC UA, Modbus, HTTP, TCP/IP, CAN, RS232/RS485.

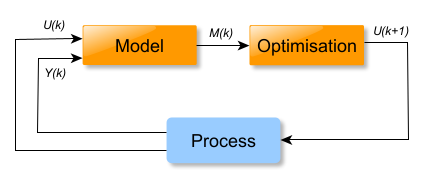

- Model-based process optimisation.

Our simulation models are always validated to the highest standards against plant data from production or prototype testing, to ensure that the simulation accurately represent the real system.

Optimal control solutions can range from simple classical feedback/feedforward to advanced control, such as model-based methods like MPC. Nevertheless, simplicity remains a key objective in our solutions, providing performance criteria can be met.

Our clients include Centre for Process Innovation, GSK and Roche.

Training

We provide onsite, industry specific and bespoke courses on a range of fundamental and advanced control engineering topics.

Industry-Specific Training

We can adapt individual courses to suit your company's industry/business.(Examples)

Looking for control improvement?