Software Services

TRAINING SIMULATORS

Simulation models enable practising engineers to link theoretical knowledge and concepts with their own real-life processes and systems. They can also help plant operators and maintenance staff become familiar with operational procedures.

What We Provide

We offer models built in various development tools, including MATLAB/Simulink, LabVIEW and Control Design and Simulation (CD&SIM) module, HYSYS, MATRIXx, and ADAMS, tailored to your training needs.

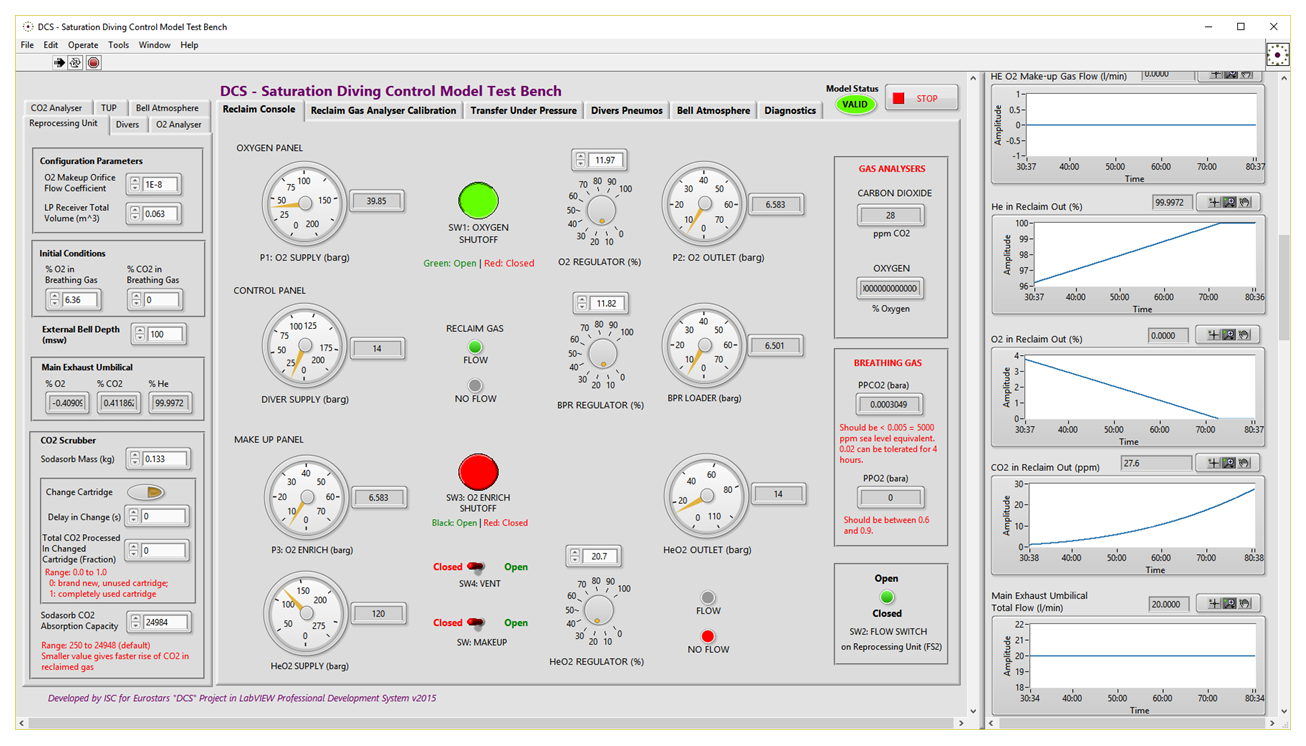

For example, we can provide LabVIEW models with intuitive graphic user interfaces (GUIs) that mimic the practical applications to enrich classroom experience of control training courses. These models can be deployed as individual LabVIEW Virtual Instruments or as standalone executables, along with training where appropriate and required.

Reasons for Using Simulators in Training

- Informed Decision-Making: Make well-informed decisions in daily operations and when performing upgrades or modifications.

- Enhanced Safety: Increase the operating envelope while maintaining plant safety.

- Confidence in Operations: Be confident in handling both normal operations and abnormal or critical situations.

- Reduced Downtime: Minimise downtime and improve profitability.

More Information

- Using Simulations for HIL

- Turbine Access System Software Presentation Slides

- 70-Ton Gripper Arm Software Presentation Slides

- Watch the presentation at NI Days 2013 about Gripper Arm Control Software