MATLAB and Simulink

WHAT WE DO WHY USE US EXAMPLES OF OUR WORK CUSTOMER FEEDBACK

WHAT WE DO

We carry out consultancy projects and provide training courses based on MATLAB, Simulink, and related MathWorks tools.

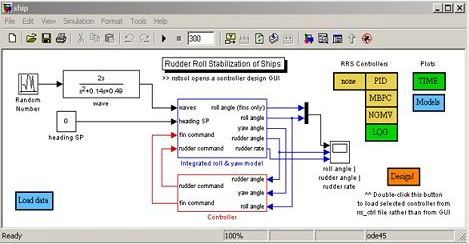

- Our consulting services include control design, process control, energy efficiency, and dynamical simulation and modeling.

- Training courses include process control, system identification, optimisation, and other control topics.

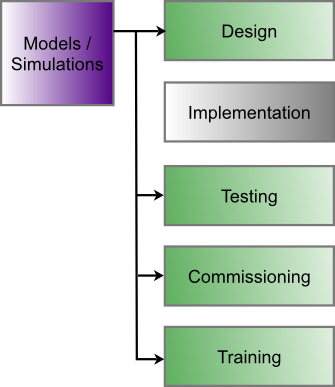

We can use MATLAB and Simulink to build properly validated dynamic models and simulation to meet your company-specific objectives.

Models can be derived from first principles or plant data. Additionally, we help clients understand the developed model to the depth they require and provide training if appropriate.

More details ...

INDUSTRIES WE SERVE

Our services are available to a range of industries:

WHY USE US

We provides an in-depth understanding of control technologies, backed by extensive experience across diverse industrial applications:

- Diverse Industrial Applications - We are actively in a wide range of industrial sectors, including .

- Expert Analysis - Renowned for our expert analysis of complex problems, we are dedicated to identifying practical and innovative solutions.

- Training Courses - Our training courses in control are designed to provide sustainable, long-term improvements in asset performance by developing in-house resources.

- Impartial Solutions - Our impartiality ensures that we provide the most appropriate solutions for our clients.

- Empowerment - We impart knowledge and empower clients to drive improvements themselves.

- Project Management and Research - We possess proven project management and research skills.