Process Control Troubleshooting

Every process plant has control issues, most of which do not appreciably impact on profitability or safety. However, there will be some that, if corrected, could significantly benefit the plant's operation through lower variability, increased throughput, reduced energy usage or reduced manual intervention. Unfortunately such problems often become accepted as the norm with the perception that a solution would be too difficult or too costly. Yet most problems can be simple and cost effective to fix - providing the problem source is known.

ISC is routinely engaged to look at process control problems that suppliers have looked at but failed to solve. We have an excellent track record in finding the real cause of problems through our special combination of theoretical understanding, extensive practical experience and engagement with all functions in a client company. Myths often abound regarding causes of such problems. Approaching a problem with an open mind is an important aspect of ISC philosophy, as is using the simplest, most cost effective solution.

System performance problems are not always due to the controller, though often they are labeled as such. ISC's approach to troubleshooting is that all aspects of the system are to be scrutinised before reaching a conclusion. Sensor, actuator, system design and operational aspects are all considered.

"Approaching

a problem with an open mind is an important aspect of ISC philosophy,

as is using the simplest, most cost effective solution."

"Approaching

a problem with an open mind is an important aspect of ISC philosophy,

as is using the simplest, most cost effective solution."

PROBE: Control Benchmarking Tool

ISC has a control benchmarking prototype tool,

PROBE, for the Microsoft Windows platform.

PROBE enables users to compare the performance of control loops against a number of

benchmarks including Minimum

Variance (MV) using off-line loop data.

(Download the Probe Flyer (PDF))

Example Projects:

- Powerstation Trips - The cause of a gas supply trip at a gas-fired combined cycle powerstation was investigated using dynamic models which allowed different resolution options to be explored prior to commissioning.

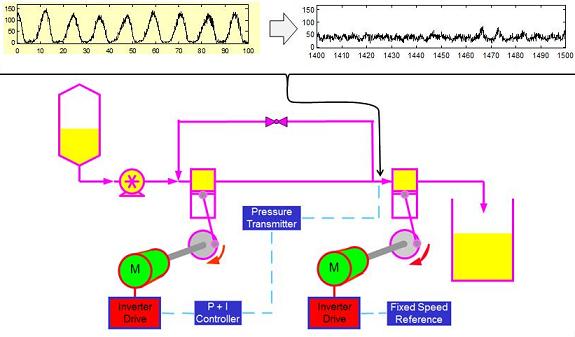

- Homogenisation Process - A food processing plant had high maintenance costs on a homogenisation process. These were arising from oscillations in a pressure control loop being caused by excessive measurement filtering. Removing the filter solved the problem. (Download project note)

Looking for control performance improvement?